Gas Detector Calibration in Singapore: The Smart Safety Choices

When you work in environments where gas leaks or hazardous emissions are a possibility, accuracy is a must. This is where gas detector calibration in Singapore comes into play. A gas detector might be a piece of high-tech safety gear. But without regular calibration, it’s like having a smoke alarm with no batteries. The consequences of a faulty reading can range from costly downtime to serious safety incidents. Professional detector gas calibration service providers in Singapore ensure that equipment measures gas concentrations precisely, meeting both safety regulations and operational needs. But calibration is a shared responsibility between the service provider and the team using the equipment. The success of this process often depends on collaboration, self-awareness, and a clear understanding of the costs involved.

Working with Calibration Experts

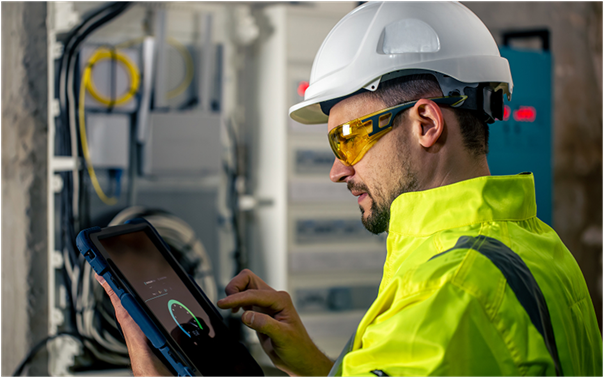

Gas detection is a field where teamwork between your internal safety team and your detector gas calibration service provider makes all the difference. Calibration technicians bring the technical expertise, but the client’s team contributes vital context about worksite conditions, types of gases monitored, and environmental factors that can influence readings.

To make the most of this collaboration, start with open communication. Share your current calibration schedule, recent incident reports, and any equipment performance issues you’ve noticed. The more specific you are, the better the service provider can adapt their calibration process to match your needs.

Another key tip is to involve your team during calibration visits. Having your safety officers observe the process builds trust and improves in-house understanding of equipment upkeep. This kind of knowledge transfer helps teams troubleshoot between service intervals and identify early signs of calibration drift.

The best results happen when both parties view calibration as part of a continuous safety strategy rather than a compliance checkbox. That mindset leads to more accurate readings and fewer unplanned disruptions.

Knowing When Calibration is Due

While most manufacturers recommend a fixed calibration interval, often every 6 to 12 months. But real-world conditions can make these timelines shorter or longer. As the end user, you are in the best position to spot the early signs that your gas detector needs attention.

Start by tracking the detector’s performance in routine checks. If readings seem inconsistent compared to past data, or if the device takes longer than usual to register changes, it may be time for a recalibration.

Environmental factors like extreme temperatures, humidity, or dusty conditions can accelerate the need for servicing, making a standard schedule insufficient.

A simple self-assessment routine might involve:

- Comparing current readings with known reference points or test gases.

- Checking for frequent false alarms or failure to alarm during controlled tests.

- Reviewing any changes in the worksite that could affect sensor performance, such as introducing new materials or processes.

By performing these checks and keeping detailed logs, you give your gas detector calibration in Singapore the insight it needs to perform a more targeted, efficient service.

Balancing Safety and Budget

Investing in a detector gas calibration service in Singapore may seem like an extra cost. But it’s more accurate to think of it as an insurance policy. The expense of calibration is minimal compared to the potential costs of inaccurate readings. These could include project delays, regulatory fines, emergency shutdowns, or harm to workers.

However, there’s still a budget to manage. The first step is to understand the full scope of what’s included in the service. Does it cover both calibration and minor repairs? Are replacement sensors or parts billed separately? Clarifying these details upfront prevents budget surprises.

It’s also worth exploring whether multi-unit service packages or annual contracts can lower per-device costs. Some companies combine calibration with other safety equipment maintenance services, allowing them to reduce total spending without compromising standards.

The key is to evaluate the cost of calibration in the context of total operational risk. By factoring in potential downtime, incident costs, and regulatory compliance, calibration shifts from being a periodic expense to a strategic safety investment.

From Maintenance to Mindset

Whether you operate in construction, petrochemical, or manufacturing sectors, gas detector calibration in Singapore services are about keeping equipment in line with factory specs and creating a safety mindset where accuracy is non-negotiable. A proactive approach, built on strong collaboration, regular self-assessment, and smart budget planning, ensures your detector gas calibration service works for you, not just for compliance purposes. When calibration becomes a natural part of your operational rhythm, it reinforces a culture of vigilance that protects both people and productivity.

If your gas detection equipment hasn’t been checked recently, now is the time to act. Schedule your next calibration with ANSAC Technology today, and empower your team with the knowledge to spot early warning signs and keep your workplace safety systems sharp.